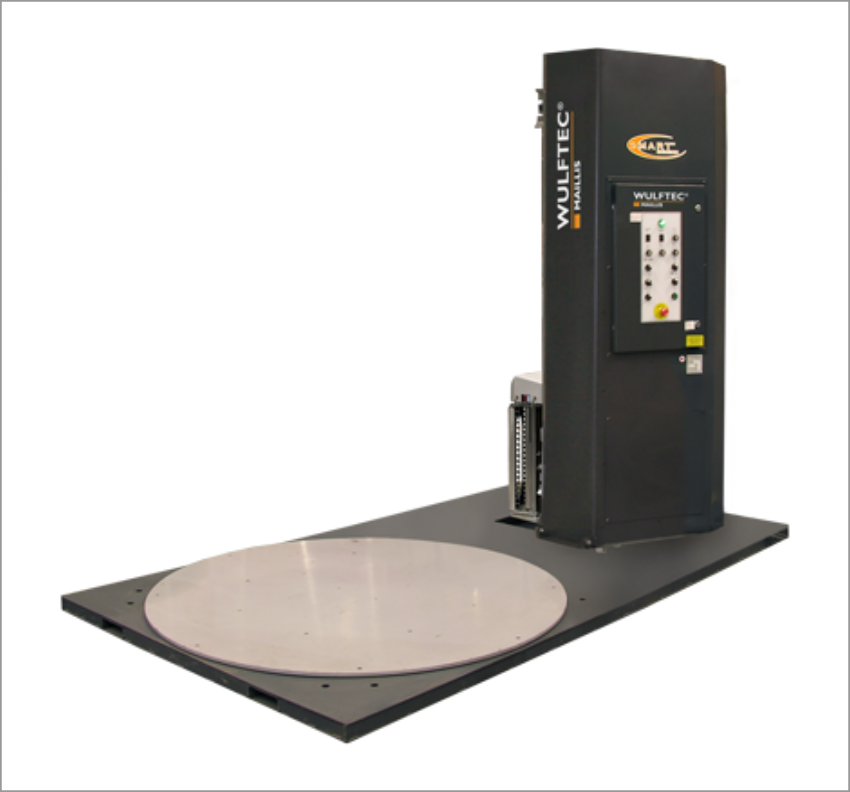

SML-200

Semi-Automatic Turntable Stretch Wrapper

Request a Quote

The SMH-200 model, a standard base high-profile turntable as the ideal stretch wrapping solution for your unique needs.

High-profile standard base stretch wrapper.

Perfect for various applications.

Features

- The Wulftec SMART Series is a competitively-priced series of semi automatic low and high profile turntable stretch wrapping systems… a smart approach to semi-automatic stretch wrapping

- With the SMART™ Series you get:

- the exact stretch wrapper you need and pay only for the features you want

- to pick and choose the individual components that will best meet your stretch wrapping needs

- a better, more competitive price

- better and quicker turnaround – now you don’t have to wait longer to get the exact machine you need - the smart series is modular in design

- to adapt without overspending

- The SMART Series™ has been designed to allow you to:

- upgrade the control panel at any time

- upgrade the base at any time

- upgrade the carriage at any time

- change the tower/wrap height at any time

- Wulftec was the first in North America to put AC variable frequency drives as standard equipment on all machines. Why? Lower maintenance and better reliability—Wulftec stretch wrappers will save time and money

- NEMA 4/12 control panel dust tight and waterproof

- The control panel is neatly organized eliminating time otherwise lost searching for wires

- The control panel is UL508A approved

- Superior Electrical/Electronic Design including Allen Bradley MicroLogix PLC and AC drives

- Easy to understand alarm signalization

- All motors, proximity sensors, photoeyes and other sensors have quick disconnect cables that simplify installation and maintenance

- Photoeyes are maintenance free and protected

- All Wulftec structures are made of heavy-duty steel for rugged performance, even in the harshest work environments. They’re built to last forever

- Dual chain driven for balanced movement & no vibration

- Quick and easy adjustment of upper and lower carriage travel

- The "Maintenance Free" spring loaded carriage gate equipped with spring loaded rollers, ensures optimal contact with the stretch film year after year, without involving maintenance

- Wulftec is the only manufacturer to offer a LIFETIME warranty on its pre-stretch rollers’ blue compound

- Preset pre-stretch ratios are available from 50-300%

- Since all of our semi-automatic SMART Series™ stretch wrappers wrap 2 inches from the turntable, you are guaranteeing the product is properly secured to the pallet, resulting in a pallet that is more stable for transport, and therefore less damage.

- No film threading is required and a Lexan cover eliminates operator's ability to reach rollers when gate is closed

- Non-Proprietary parts accessible on a local base

- The best warranties in the industry

- 5-year unlimited cycle warranty

- lifetime warranty on prestretch rollers

- 10-years on the steel structure

Specifications

- Production Rate

- 55 loads per hour

- Machine Dimensions

- 119.50" L x 66" W x 86.50" H

- Load Weight

- 5000 lbs

- Approximate Shipping Weight

- 2500 lbs

- Electrical Requirements

- 120 V

- 1 ph

- 60 Hz

- 15 A

- Controls

- Allen Bradley MicroLogix 1000 or 1200 PLC

- 24V control system

- Current overload protection

- NEMA 4/12 control cabinet

- Autoheight sensing photoeye

- Power light indicator (Basic)*

- Power On/Off switch and status light (Standard)*

- Start/stop push button

- Large emergency stop (push / pull type)

- Manual carriage up/down function

- Variable table speed (16 RPM) with automatic home position

- Carriage speed adjustment

- Top and bottom wrap selectors

- Reinforced wrap/manual rotation control

- Film tension adjustment

- Lack of film alarm

- Structure

- 14 gauge formed steel tower

- Forklift Portable base design from both ends

- Heavy duty structural steel construction

- Film Delivery System

- 20" NO-THREAD® Powered Pre-Stretch Carriage

- 1 HP AC motor with Allen Bradley variable frequency drive

- Lifetime warranty on pre-stretch rollers blue compound

- Film force release for easy pull at start and end of cycle

- 50-400% pre-stretch ratio (preset to customer spec, Std 200%)

- Electronic film tension control with analog sensor

- Film roping bar

- Lexan roller cover for operator safety

- Proximity sensor on carriage gate to ensure gate is properly closed

- Film Carriage Drive

- 1 HP AC motor with Allen Bradley variable frequency drive

- Two #50 carriage lifting chains enclosed in tower for safety

- Bearing supported maintenance free guide wheels

- Turntable

- 51" x 51" octagonal table 1/4" thick

- 4 casters with polyurethane coating and tapered roller bearings

- 13 1/4" table height

- Turntable Drive

- 1 HP AC motor with Allen Bradley variable frequency drive

- 0-16 RPM variable speed

- #50 ANSI heavy duty chain drive

- Electronic soft start/stop

- Positive turntable alignment controlled by proximity sensor

- Technical Information

- The machine is provided with a manual including electro/mechanical schematics and drawings, troubleshooting guide & Installation instructions

- Notes:

- * Optional

- Production rate based on load configuration and machine options

- Overall dimensions of machine in operation

- All machine specifications are subject to change without prior notice

- Please consult your distributor for prices.

- Please note that retrofits are to be installed by a Certified Wulftec Technician.

Options

- Carriage

- 20" hydraulic carriage (no pre-stretch)

- 30" hydraulic carriage (no pre-stretch)

- 30" NO-THREAD® Powered Pre-Stretch Carriage

- Carriage adaptor bracket for 20" film on 30" carriage

- Manually Adjustable Dual Roping Bar

- Manually Adjustable Single Roping Bar

- Pneumatic roping dual

- Pneumatic roping dual - extra photoeye

- Pneumatic roping single

- Rapid Cut - Basic panel

- Rapid Cut - Standard panel

- Clamp

- SMART start clamp & pull cord

- Controls

- Economy Panel

- Foot pedal start / stop

- Lanyard remote

- Pull cord

- Remote push button station

- Safety control lockout

- Upgrade from basic to deluxe

- Upgrade from Basic to Standard

- Upgrade from Basic to Standard Plus

- Upgrade from Standard to Standard Plus

- Warning Alarm / Horn

- Warning flashing light

- Wrap sequence for basic panel

- Extension

- Wrap height extension - 104in

- Wrap height extension - 116in

- Wrap height extension - 128in

- Wrap height extension - 92in

- Motors

- Wash down motors

- Wash down motors

- Paint

- Custom color

- Epoxy paint

- Steel-it paint

- Photoeye

- Dark load detection

- Ramp

- Ramp

- Ramp extension

- Ramp with scale option selected

- Safety

- Safety fencing

- Safety fencing for dual turntable units

- Safety light curtains

- Safety light curtains for dual turntable units

- Scale

- Electronic scale

- Temperature package

- Air Conditioner (104°F / 40°C and up)

- Cold A (32 to 41°F / 0 to 5°C)

- Cold A (32 to 41°F / 0 to 5°C) - Deluxe panel

- Cold B (5 to 32°F / -15 to 0°C) - Deluxe panel

- Cold B (5 to 32°F / -15 to 0°C) - Standard panel

- Cold C (-31 to 5°F / -35 to -15°C)

- Cold C (-31 to 5°F / -35 to -15°C) - Deluxe panel

- Fan & Exhaust

- Top platen

- Electric top platen

- Transformer

- Customized transformer

- Standard transformer

- Transformer for Cold C temperature package

- Turntable

- 90° exit

- Free roller top

- Free roller transition

- High speed 24RPM

- Second turntable